-

Gas Safe Registered & Certified

Our team is fully certified and highly-trained, with years of experience on commercial and residential systems.

Gas Safe Registered in Commercial and heating services for businesses in London. Commercial heating and Vaillant Boilers, Gas safety check and Boiler repairs, Vaillant approved installer, Commercial catering inspection, Valliant boiler replacement . Commercial Heating Repairs, Commercial Boiler Breakdown, Commercial Boiler Installation Gas Mechanic Services, Commercial Heating Mechanic Repairs

-

Our core mission

Our core mission is to safeguard learning environments by providing specialist gas safety testing and inspections, ensuring every school kitchen, laboratory, and plant room is compliant, safe, and secure for students and staff.

We understand that true safety is the essential foundation upon which great education is built. It is our fundamental responsibility to ensure that the spaces where students discover, create, and thrive are free from preventable hazards. Our team of certified specialists goes beyond simple compliance checks; we conduct meticulous, in-depth assessments born from a deep understanding of the unique demands of educational facilities.

This unwavering commitment to excellence provides school leaders and facilities managers with the certified assurance and complete peace of mind they need. By guaranteeing the safety and integrity of their gas systems, we empower them to focus on what they do best: shaping the next generation.

-

CP17 Comprehensive Plant Room Gas Safety

CP17 service offers a detailed safety inspection of specified appliances within your plant room. We verify safe operation, check ventilation, safety devices, and general integrity, ensuring full compliance with current gas safety regulations. This is a crucial annual requirement for businesses.ion goes here

-

CP42 Commercial Kitchens Gas Safety Check

Specifically designed for high-demand commercial kitchens, our CP42 check covers all accessible gas appliances and associated pipework. We rigorously inspect ventilation, interlocks, emergency stop functionality, and appliance integrity, ensuring compliance with standards like BS6173:2009 and IGEM/UP/19 for ultimate kitchen safety.

-

CP16 Visual Inspection & Pressure Testing

Essential for new installations or significant modifications, our CP16 service provides a meticulous visual inspection and pressure tightness testing of your gas installation. We identify any leaks and ensure your system conforms to the Gas Safety (Installation and Use) Regulations 1998 (GSIUR), guaranteeing safety before operation.

-

CP15 Full Commercial Boiler Servicing

Maintain peak performance and safety with our CP15 full servicing of commercial boilers. Following manufacturer instructions, we conduct thorough cleaning, combustion analysis, control checks, and ensure efficient operation. Regular servicing is key to extending boiler lifespan and complying with GSIUR 1998.

-

School Laboratories

The Mandatory Safety Check: Gas Pressure Proving

The IGEM/UP/11 standard mandates that whenever an AIV is used, the system must perform a "downstream integrity check" before the gas can be turned on. This is a critical automated safety feature that prevents accidents.

This check, performed by a gas pressure proving system, ensures no gas taps have been left open before the main valve opens. Here's how it works:Description goes here

-

Gas Safety in Food Technology Rooms

Food technology areas present a unique gas safety challenge. Unlike a science lab with fixed benches or a commercial kitchen with a large extraction canopy, these rooms often feature multiple domestic-style gas cookers spread throughout the space. This makes it difficult to design a single, cost-effective ventilation system that efficiently removes both the products of combustion and cooking fumes from every appliance.

UK safety standards acknowledge this difficulty and provide specific, technology-led solutions to ensure student and staff safety.

-

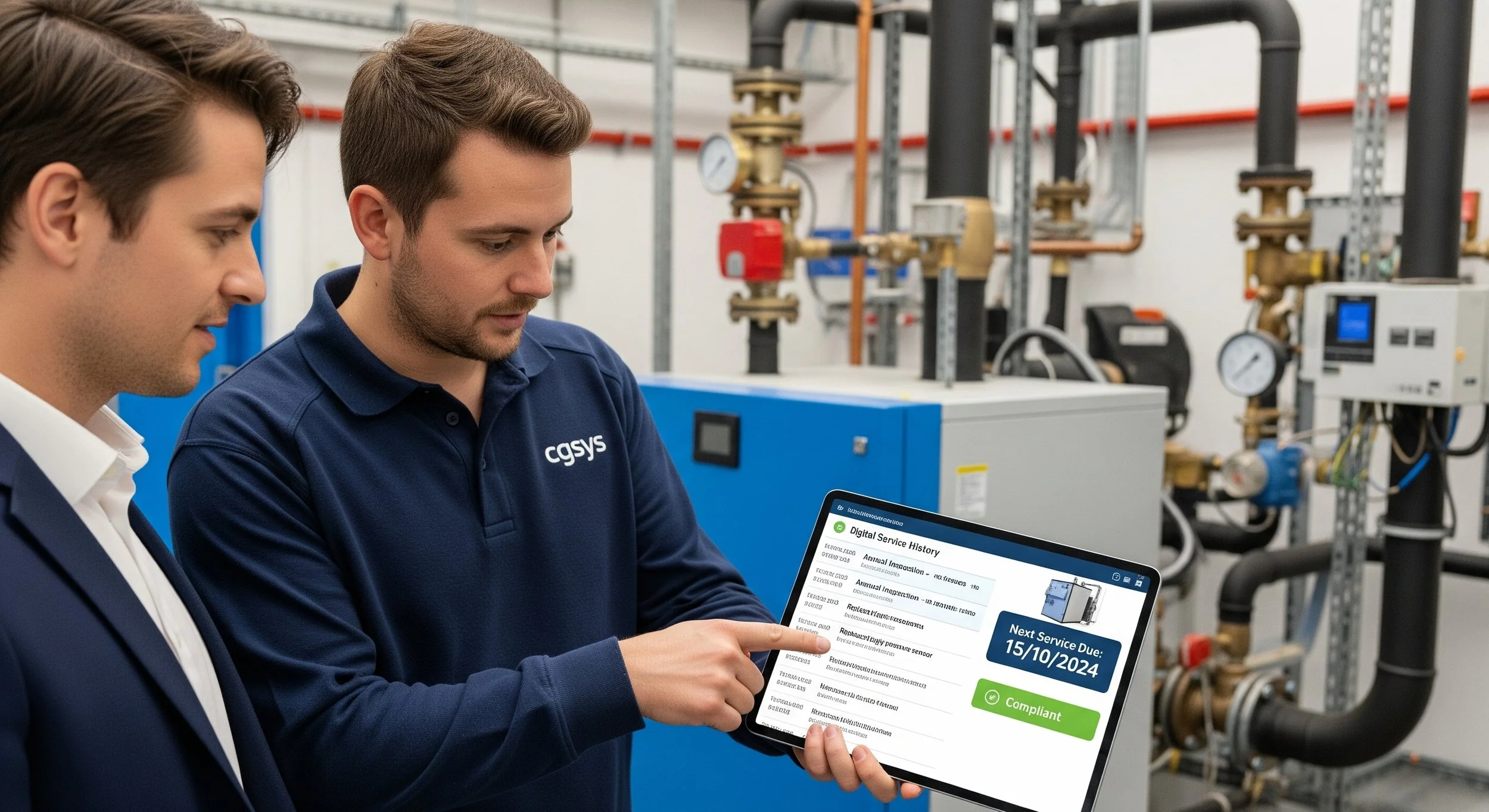

Fully Paperless System

All documentation, from service records to certificates, is sent instantly to your email as a clear PDF.

Responsive & Accountable

We outline clear processes for emergency/out-of-hours work and variations to work, ensuring flexibility and responsiveness while maintaining transparency and clear communication.

-

Complete Digital History

We maintain a full service and repair history for your appliances, providing service reminders to keep you compliant.

-

Heating System Dosing & Maintenance

Beyond standard servicing, we offer vital services like heating system inhibitor dosing to prevent corrosion and scale, ensuring optimal boiler efficiency and system longevity. Our comprehensive checks also cover expansion vessels and Pressure Relief Valves (PRVs), critical for system safety and performance.

-

Installation & Systems

New Installations & System Upgrades

Whether you require a new gas installation, a complete system upgrade, or specialized commercial interlock systems, our team delivers expert solutions tailored to your specific needs, ensuring optimal performance and compliance with all relevant standards.

-

Gas Safety for the Education Sector

We provide expert, compliant gas safety solutions for schools and colleges, covering boiler rooms, catering kitchens, and science labs.

Specialist Education Sector Solutions

We provide compliant gas safety solutions specifically for the education sector, addressing the unique requirements of boiler rooms, catering kitchens, and science labs in schools and colleges, ensuring a safe learning environment.

-

Breakdown & Repair

We offer commercial boiler breakdown and repair services for all major brands. Our 24/7 emergency response minimises downtime for your business.

We Specialise in All Major Boiler Brands

Our highly experienced team can install, service, and repair boilers from leading manufacturers, including:

Vaillant • Worcester Bosch • Buderus • Ideal Concord

-

Specialist Installations

Underfloor Heating Installation & Servicing

Solar Hot Water System Repair

Solar Hot Water & Panel Installation

Hot Water System Repair

-

Servicing & Compliance

We provide routine central heating inspections and servicing to ensure your systems are efficient and compliant with all gas safety regulations.

London-Wide Coverage

We provide our full range of heating and plumbing services to residents and businesses throughout London.

-

Commercial Systems

Commercial Heating Repairs

Commercial Boiler Breakdown & Installation

Commercial Gas Interlock Systems

Gas Mechanic Services

Emergency & Safety

Emergency 24hr Boiler Installation

Emergency Gas Leak Repairs

Gas Safety Certificates (for Landlords & Commercial)

Gas Safe Registered Engineers